- Home

- About us

- Products

- Static Grounding & Bonding Solutions

- Static Grounding Devices

- Leakage Detector

- Overfill Protection Devices

- Overfill Protection & Grounding System

- Retractable Grounding Reel

- Surveillance Radar

- Magnetic Price Sign

- Density Meter

- Laser Methane Detector

- Mass Flow Meter

- Rotating Turbo Nozzle

- Fuel Dispensers

- Batch Controller

- Positive Displacement Meter

- Satatic Grouding System

- Faqs

- News

- Certificate

- Contact us

Rotating Turbo Nozzle

- group name

- Rotating Turbo Nozzle

- Min Order

- 10 piece

- brand name

- ALPTEC Static Grounding Solutions Manufacturer

- model

- 20#

- Nearest port for product export

- Qingdao Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, D/P D/A, PayPal, Westem Union

- update time

- Wed, 11 Feb 2026 17:18:36 GMT

Packging & Delivery

-

Min Order10 piece

Briefing

Detailed

Designed for high-pressure,

high-impact car cleaning applications, including: wheel washing, floor washing,

brush pre-washing and foam washing.

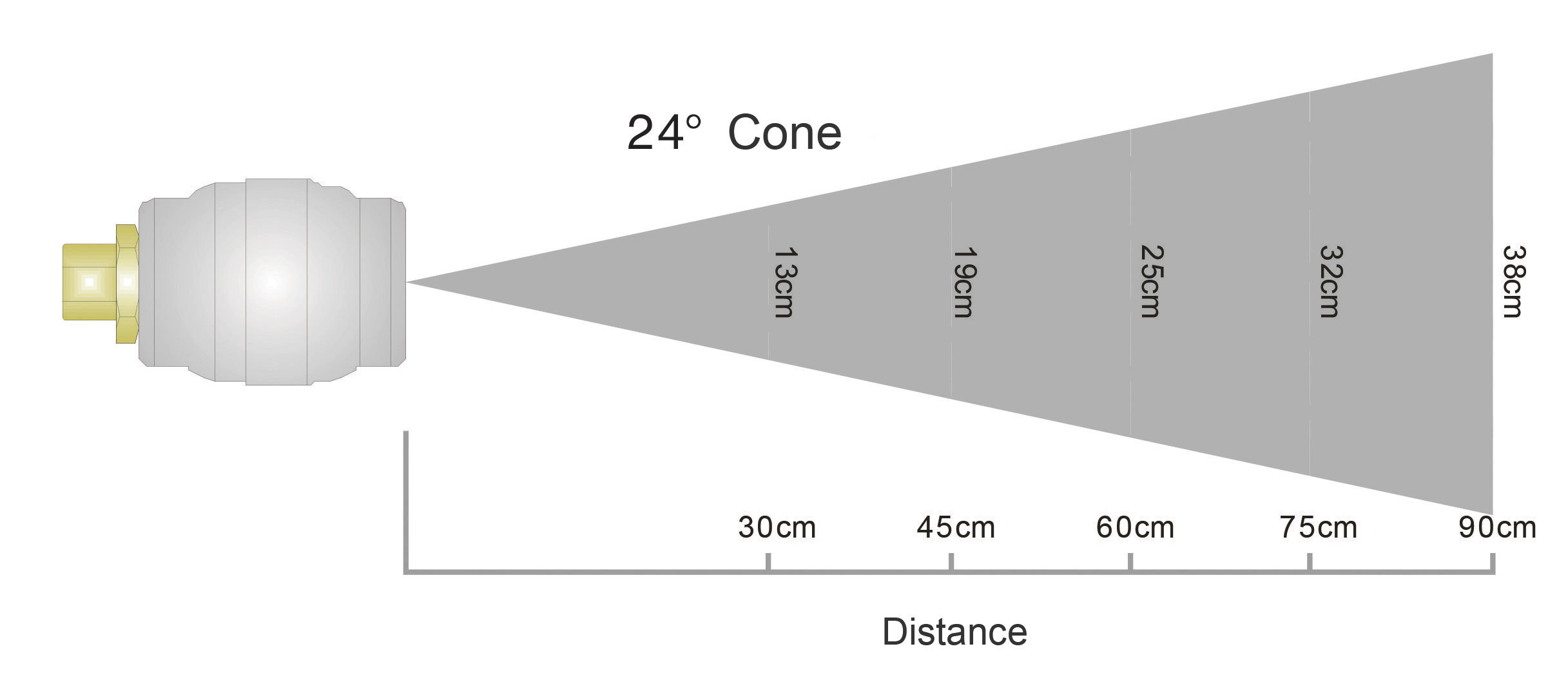

• Greater Impact: The Blast-Tec Pro blasts a 0° straight water stream at 1000 PSI,

while the stream rotates at 1500-2500 RPM to provide a 24° cone of coverage.

• Less Water – Improved stream quality results in greater impingement, allowing

you to use a smaller nozzle size while getting the same impact as nozzles with

higher GPM flow rates.

• Heavy Duty – Corrosion-resistant stainless steel housing and precision machined

tungsten carbide wear surfaces offer long life and smooth operation.

• Long Lasting – The minimal number of components reduces complexity for better

reliability-5 times the life of the market competing products. The provision of

repair parts extends the overall service life and reduces operating costs.

SPECIFICATIONS

Operating Pressure at Nozzle: 5.5Mpa-7.5Mpa

!WARNING! The correct water pressure is what

causes the rotor assembly to rotate properly. Setting pressure too low may

cause failure to rotate or laser. Setting pressure too high may cause nozzle to

fail prematurely

Water Temperature: 49℃ Max

PH 5.5-8.5 Water Quality:

Must be PH neutral. 5.5 - 8.5 PH

Water Filtration: 100 micron

filtration recommended.

31cm-80cm Optimal Operating

Distance: 31cm-90cm

G1/4 Imported thread:

internal thread G1/4

NOZZLE SELECTION AND SIZING

Proper nozzle selection

should take into consideration the type of application, your pressure setting distance

from the substrate, and the nozzle number size.

Pump Capacity –The pump must

be able to generate the flow required by all nozzles at 6Mpa.

For

example, a wheel blaster with three #3 Nozzles (6LPM per nozzle) on each the

driver’s and passenger’s side (total of 6 nozzles) will require pump capacity

of 18LPM at 6Mpa.

Flow

|

Nozzle

number |

Flow (under 6Mpa pressure) LPM |

|

20# |

3.9L |

|

25# |

5L |

|

30# |

6L |

|

35# |

7L |

|

40# |

8L |